The RINGS high-speed separation method using “SPECIAL SHAPED RINGs” overturns the common sense of conventional separtion technique of solids in water!! Separates the solids of 7 microns or over, leading to scale-forming components in water, such as Calcium, Magnesium an Iron. (SS:Suspende Solid) You can get “MENTENANCE FREE” with the control Unit System ¡ Challenge for the ultimate water saving with the NEW Rings high-speed Separation method. Separates and efficiently removes the “Sands” that were mixed into the cooling tower form the air and that will scartch the surface of the pipes!

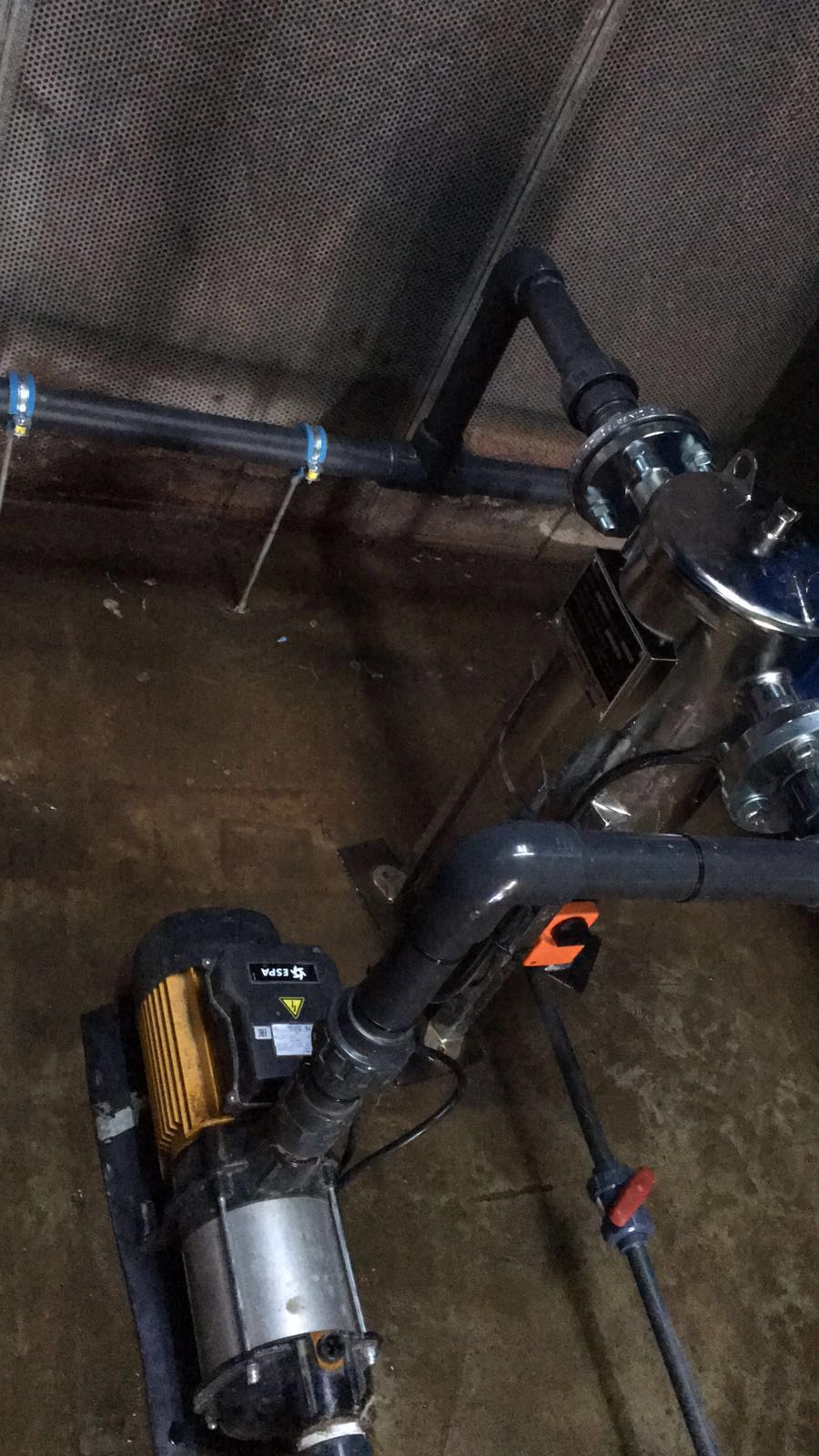

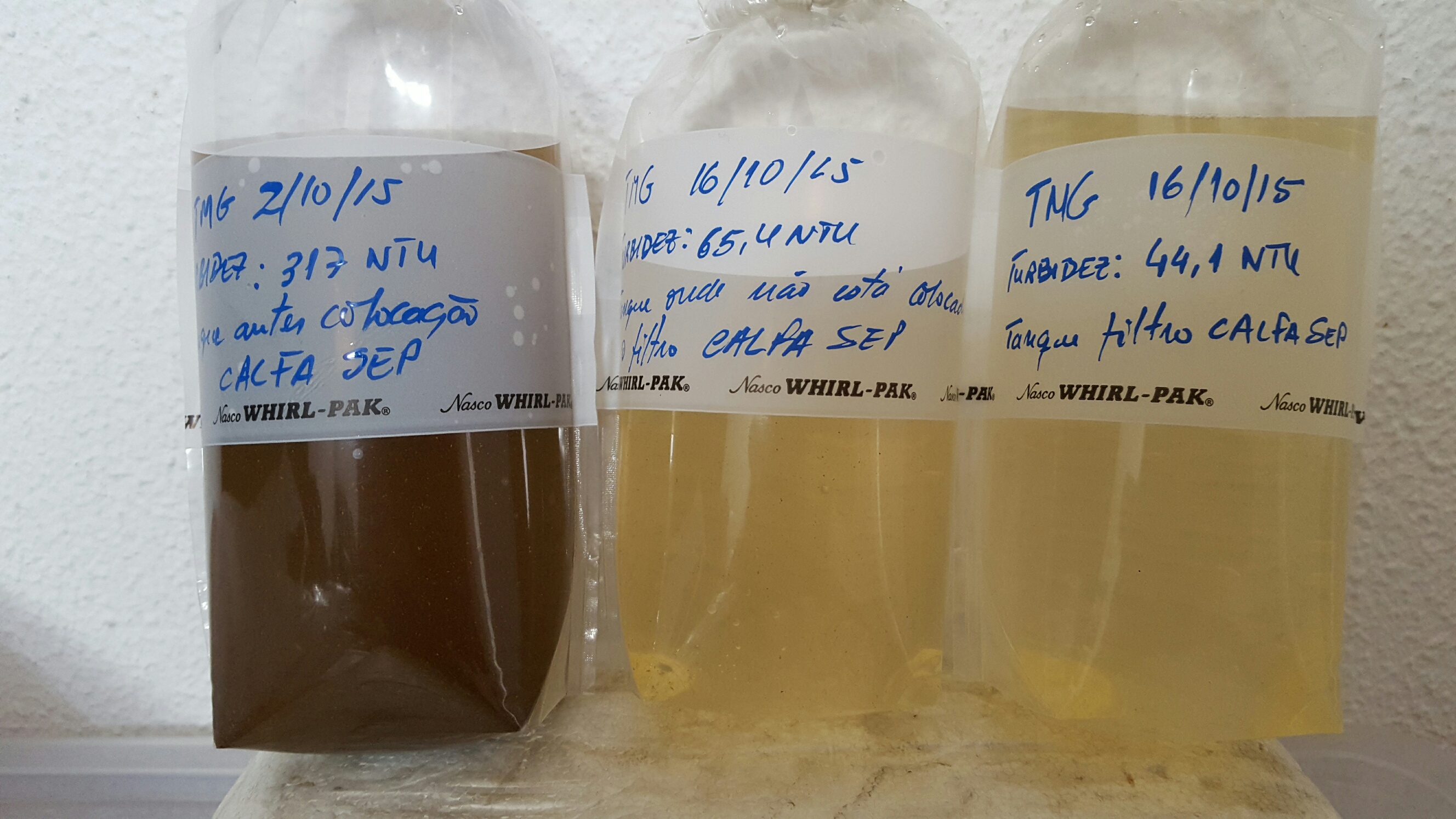

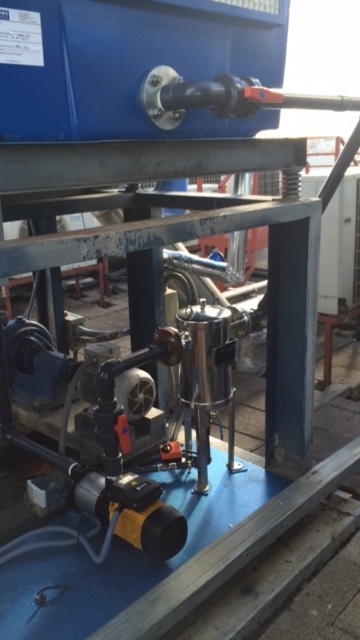

Rings High-Speed Separation using special shaped rings. The Separator System For Solids in CALFA “SEP” can separate the solids (impurities) in water in the lower, concentrate them in the bottom, and then drain them out easily.

Using it together with our “Environmentally Friendly Water Treatment, “CALFA BAS” coagulates and concentrates the solids in water efficiently, and extracts only dirty water with high turbidity and high hardness that can adversely affect the system.

Unlike a Sand Filter, “BACK WASH” which needs to be conducted frequently is not required. Selected solids collection options ensure minimum water waste and easy discharging of solids collected. Therefore, a remarkable “Water Saving” can be achieved.

CALFA BAS`s cleaning reaction, dissoving and removing Silica Scale from Solid to Liquid safety, and Scale Prevention and Anti-Corrosion effect within Equipment and Pipes helps the equipment to be always kept in good condition and to achieve optimal heat exchange rate. Consequently, a outstanding remarkable “Energy Saving” can be obtained.

Our NEW “Water Treatment Technique” that is able to achieve “Water saving”, “Energy saving”, “Human health” and “Environmental conservation”at the same time. In future, this superior technique will be implemented in the world, and then will become the “GLOBAL STANDARD”.

Other features:

- No Replacement of Sand Media or filtering materials is required.

- NO BACKWASH or Maintenance is required.

- Automatic drain vlave can be installed

- Able to remove solids in water up to 7 microns in particle size

- Heat Resistant 110ºC

- Low pressure loss: 0.012MPa (0.12Kgf/cm2 or lower)

- Pressure Resistant 1.57MPa (16kgf/cm2)

CALFA “SEP” can separate any solids in water heavier than “water” (specific gravity :>1.0). The following table shows the “Specific Gravity” of some common metals in cooling water.

Water |

1,0 |

||

Limewater(CaCO3) |

2,8 |

Aluminium |

2,7 |

Sand, silica (SiO2) |

2,6 – 2,8 |

Zinc |

7,1 |

Soil, Silt |

1,2 – 2,0 |

Iron |

7,8 |

Carbon |

1,8 – 2,5 |

Steel |

7,8 |

Anthracite |

1,3 – 1,9 |

Nickel |

8,9 |

* The actual specific gravity will be higher due to the chemical coagulation of CALFA BAS.

Conventional water filtration systems, “Sand Filter” was popular & general systems. However, it has some problem that difficult to install for tower buildings, because of “space is not enough” “too large” and “too heavy” etc. of course NO space to install water tank for back wash.

Also, needs to do “tough maintainance “ frequently, Back Wash, replacing filtration media, if not, sand media would be congealed and occur lowering of filtration performed. Eventually , many clientes no often use it in spite of spent a large amount of expense.

CALFA SEP no needs wide space, big expense for back wash, media replacement. It`s able to carry by hands of human easy to install. You can start to water purification with CALFA “SEP” soon!

PRODUCTS LINE UP

CALFA “SEP”/Cooling Tower/Pump/Combination Table

MODEL |

(IN / OUT)ФA |

SPEC recommendation |

|||

SEP Flow(m3/h) |

Recommended PumpkW |

Cooling Tower(RT) |

Cooling Tower Flow Rate(m3/h) |

||

PS-40AA |

40A |

8 |

0,75kW |

150RT |

͠ 160 |

PS-50AA |

50A |

10 |

0,75kW |

250RT |

160 ͠ 200 |

CA-1 |

50A |

20 |

1,5kW |

500RT |

200 ͠ 400 |

CA-2 |

65A |

28 |

2,2kW |

700RT |

400 ͠ 560 |

CA-3 |

80A |

40 |

2,2kW |

1000RT |

560 ͠ 800 |

CA-4 |

80A |

60 |

3,7kW |

1500RT |

800 ͠ 1200 |

CA-5 |

100A |

100 |

5,5kW |

2500RT |

1200 ͠ 2000 |

CA-6 |

150A |

160 |

11,0kW |

4000RT |

2000 ͠ 3200 |

CA-7 |

150A |

240 |

18,5kW |

6000RT |

3200 ͠ 4800 |

* For “Side Stream Type” users (generally, select this type)

* Select this type to install a side steam filter fot the existing cooling tower.

* Calculate “5%” (standard) of the circulation water quantity, and select the “type” to match the water treatment flow rate required.

Demostrative Videos:

Copyright © 2016 Calfa Europe S.L. All rights reserved.